RESPONSIBLE CONSUMPTION AND PRODUCTION

The SDGs arise from challenges like the economy, ecology and society. Universities can effect changes in these sectors through their enterprising talent pool, the spirit of learning and disseminating information, a conviction for change; their capacity for research and innovation, and their ability to engage public stakeholders in implementing projects. Containing consumption is a self-explanatory answer to the problem of sustainability. Beyond that, what is necessary is to outline meaningful measures backed by practical and scientific methods to increase sustainability exponentially.

Nitte (DU) practices responsible consumption and production:

The globally accepted model towards improving sustainability is Reduce, Reuse and Recycle. At Nitte University, we have endeavoured to identify, create and implement processes to improve every area of the 3R model and continuously improve on the same.

The University has established facilities for socially relevant action and has built a capacity to identify and respond to societal needs. Creating awareness in terms of production and consumption.

Nitte (DU) administration and eco-sensitive measures:

Nitte (DU) tracks water requirements, wastewater generation and water recycling. It is done to create awareness about water conservation

amongst its stakeholders. An annual water audit is undertaken across the University to assess per capita consumption. The audit provides a clear picture of consumption and helps formulate containment and improvement measures.

Water: Rain water from roofs is collected using separate pipelines. This water is collected in raw water storage tanks and then treated in a WTP consisting of a pressure sand filter and activated carbon filter. Additionally, the chlorine demand of the water is assessed, and the required dosage (Sodium hypochlorite diluted to 10%) is provided using automatic dosage pumps.

The water is used for all domestic purposes.

- Use of water-retaining material like cloth/ gunny bags etc., during curing

- Ponding” for retaining water on flat concrete structures for curing

- Use of curing chemicals/techniques to minimize water requirements

- Use of non-potable water for construction activities

- Use of water-efficient plumbing fixtures like push-cock taps

- Use of sensor-based taps

- Use of aerators, pressure inhibitors and flow regulators to ensure a constant flow

- Separate pipelines for potable water, water for recycling and treated water are provisioned for during construction

- Provision for rainwater harvesting

- Provision for management of stormwater

- Rainwater storage ponds have been created on the campus for the storage of stormwater

- Rainwater from an artificially created storage pond is used from an external location near the campus. An MoU has been signed with the land-owner for the use of this water

- Push cock taps are being used as a replacement for ordinary taps to reduce water wastage.

- Old bore wells are flushed to facilitate the recharge of groundwater.

- Recycled water is used for flushing toilets and in gardens

- Restrictions on the use of bottled water to reduce plastic waste.

- Board rooms are equipped with water filters and dispensers to avoid bottled water.

Nitte (DU) has established STPs of various capacities on all campuses. Effective utilization of treated water. Additionally, all buildings have catered to dual plumbing lines for toilets.

- Use of recycled water for flushing and gardening

- The wastewater is collected and treated in Sewage Treatment Plants (STP).

- Three campuses have individual STPs. The KSHEMA campus has an STP plant with a handling capacity of 4,00,000 litres/day.

- University and Hospital campuses have a plant of 8,00,000 litres/day, and the Paneer campus has a plant handling 2,50,000 litres/ day

Two methods of treatment at the STP are used:

- I. Sequencing Batch Reactor (SBR) System

- II. Continuous Process (Activated Sludge Process)

The process has the following steps:

BAR SCREEN CHAMBER The function of the bar screen is to prevent the entry of solid particles/ articles above a specific size, such as plastic cups, paper dishes, polythene bags and sanitary napkins, into the STP.

EQUALIZATION TANK The equalization tank is the first collection tank. The primary function is to act as a buffer, collect the incoming raw sewage at widely fluctuating rates, and pass it

on to the rest of the STP at a steady flow rate.

AERATION TANK Aeration is the heart of the treatment system. The primary function of the Aeration tank is to maintain a high population level of microbes. This mixture is called MLSS (Mixed Liquor Suspended Solids). Here the sewage is mechanically aerated for a calculated time and left for settling. The clear water is then taken out using decant valves

INTERMEDIATE SUMP: Clearwater coming out of the decant valve is collected here. PRESSURE SAND FILTER (PSF): This unit is a pressure vessel. It is used as a tertiary treatment unit to trap the trace amounts of solids which escape the clarifier

ACTIVATED CARBON FILTER (ACF) • This is a tertiary treatment unit. • Activated carbon is typically manufactured from coconut shells or charcoal. • It improves multiple quality parameters of the water: BOD, COD, clarity

(turbidity), colour and odour.

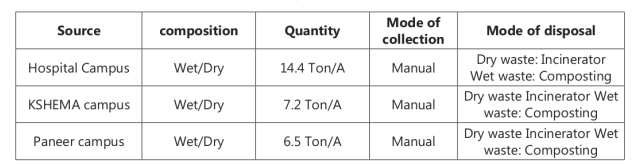

Solid waste: The University generates approximately 28.1 Tons/A. The wet waste and dry waste are sorted at the source. The biogas unit recycles organic waste to utilize common kitchen waste.

A composting facility is available on the Paneer campus to utilize organic waste. The wet waste is put into the composting pit, and dry waste is disposed of using the incinerator. Waste segregation is done at source in the hospital, laboratories and common areas. Dedicated bins for waste management are made available - Green for degradable, Blue for plastic and metals, and Red for e-waste and batteries. Bins are placed in prominent positions on each campus, with instructions displayed for public awareness.

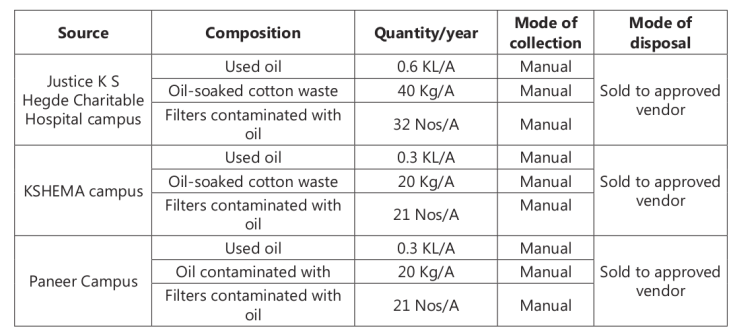

Medical waste:

Strict compliance with provision for disposal of bio-medical and electronic waste. Chemical and hazardous waste from laboratories is sent to a certified agency (RAMKY) for processing, and no part of the waste is disposed of elsewhere. Chemical and hazardous waste from laboratories is sent to a certified agency (RAMKY) for processing, and no part of the waste is disposed of elsewhere.

Solid waste:

The University generates approximately 27 Ton/A. The wet waste and dry waste are sorted at the source. The biogas unit for recycling organic waste to utilize common kitchen waste. Waste segregation is being carried out; organic waste is composted in-house, and the manure generated will be used for the gardens on the campus. The composting pit is a recent addition to the campus. Paper waste:

Separate collection of paper waste for recycling. Paper waste is sent to an external recycling unit vendor.

Paper usage is minimized, and the University has developed an online information system which reduces paperwork. The double-sided printing option is being used at terminals with access to printers. Student records are maintained online. The purchase department encourages using eco-friendly materials that are recyclable or made from recycled material.

Plastic waste:

Reusing scrap material. Encouraging the use of eco-friendly materials in construction. The use of paper/plastic cups/bottles is strongly discouraged.

Required materials are indented by the material in charge of that particular department and are approved by the Head of the department and the institution; materials are then received from the store with the bill and distributed to the concerned.

Energy

- a. Conventional light fittings are being replaced with energy-saving lights in a phased manner.

- b. VFDs have been installed in all critical areas, which help reduce motors’ running costs and life.

- c. Solar panels have been installed on all campuses to generate electricity and contribute towards the green initiative. Additionally, solar water heaters have been installed in all hostels.

- d. Synchronization panel/ Load manager has been provided for DG sets at all campuses to ensure optimum power generation utilization.

- Intending to contribute towards the green initiative, the University has entered into an open access agreement for Hydro & Wind energy with M/s.AMR Power Pvt Ltd, M/s. Doddanavar Global Energy Pvt Ltd and M/s. Brindavan Hydropower Pvt Ltd.

- Periodical Maintenance / AMC of all electrical equipment, including panels, carried out per schedule. Additionally, all critical equipment has been provided with closely monitored AMC, which helps enhance the equipment’s life and reduce the time between failures.

- Emergency lighting is connected to inverters which help in emergencies. h. All ACs beyond economical repair are replaced with 5-star inverter ACs with R32 Refrigerant gas.

- Heavy Duty Capacitors have been installed for longer life to maintain a Power Factor within the range (of 0.9 to 1).

- XLPE UG cables are being used for all new installations, which helps maximize cable life and reduce expenditure. FRLSH copper wires are being used at all new installations.

- All old main panels in installations are being replaced in a phased manner with Single phase, Under / Over voltage protection switchgear products.

- Timers have been installed at various locations for switching on/ off security lights, which helps minimize energy consumption.

- The concept of ensuring that in the event of a power failure, all non-critical ACs

- are disconnected from the DG supply is vigorously pursued. Towards this, the same has been implemented in KSHEMA and will be taken in other installations in a phased manner.

Awareness programs:

-

Water conservation projects with the

community:

- Updates on biomedical waste management during COVID-19: The Indian scenario. Chand S. Shastry C.S., Hiremath S., Joel J.J., Krishnabhat C.H., Mateti U. Clinical Epidemiology and Global Health Volume 11, July–September 2021, doi.org/10.1016/j. cegh.2021.100715

- Biofilm characterization in removal of total chemical oxygen demand and nitrate from wastewater using draft tube spouted bed reactor. Joshi K, Navalgund L, Rathod K, Shet V.B, Srinikethan G, Shet T, Rachitha U, Anand A. Biotechnol Lett 2021 Oct;43(10):2001-2009. DOI: 10.1007/s10529- 021-03181-3

- Micro Climate Modifications

- Efficient Water Cycle

- Clean Energy

- Ecological and Biodiversity Enhancement.

Rejuvenating the Vrishabhavathi river through addressing the built (a student project by Ms Kavya Amin, Nitte Institute of Architecture), this proposal aims to develop the canal edge by providing the ideal green buffer space for the development of the ecosystem, which further enhances the engagement of the people with the water body. The urban fabric needs to be moulded in such a way as to encourage the community spaces in and out to connect with the natural sources present around them. The proposal aims to combine a housing typology and the urban green spaces to develop an ideal scenario in layering the urban fabric.

SUSTAINABLE DEVELOPMENT GOAL - LECTURE SERIES

Nitte (DU), in association with Staff Development Centre, organized a Workshop on “One health and One Planet-Responsible consumption and production,” conducted on 28th December 2021. Prof (Dr) M.S.Moodithaya, Pro-Vice Chancellor, delivered the opening remarks. Principal and Dean, Prof.(Dr) U.S Krishna Nayak welcomed the gathering; Prof (Dr) Smitha Hegde, Deputy Director, NUCSER, was also present and expressed her views. The program was moderated by Dr Sowmya M. K, Co-ordinator for SDG Chapter 12. The speaker of the day was Dr Mamatha Mishra who is the National Resource Person FSSAI, Secretary AFSTI Bengaluru chapter, founder GTFT. She emphasized on the importance of responsible production and why do we need it today, stressed on farming and farmers, food cycle the sustainability of food production. There was a discussion on conservation of biodiversity and oil palm, according to Dr Mishra supply and demand which goes hand in hand taking into consideration it all depends on the need.

Clothing drive:

Three collection centres were set up at different locations within the campus. Clothes from faculty, students and others were collected at these centres and brought to a central warehouse where they were graded into three separate groups for easier and faster recycling.

Research Publications:

Opportunities and challenges:

Nitte (DU) is poised to expand its campus in Mangalore. Aligning with the eight missions identified under National Action Plan for Climate Change, the following fundamental concepts have been considered in the campus master planning process:

.png)